Design and Manufacturing of Composite Materials

With a steadfast commitment to excellence and advanced CNC machining capabilities, we specialize in transforming a diverse array of composite materials into finely crafted components that meet the highest standards of quality and performance. Whether you're looking for reliability, precision, or versatility in composite machining, Tektonics is your trusted partner for turning concepts into reality.

CNC Routed MDF

CNC Machined Richlite

CNC Routing Plywood

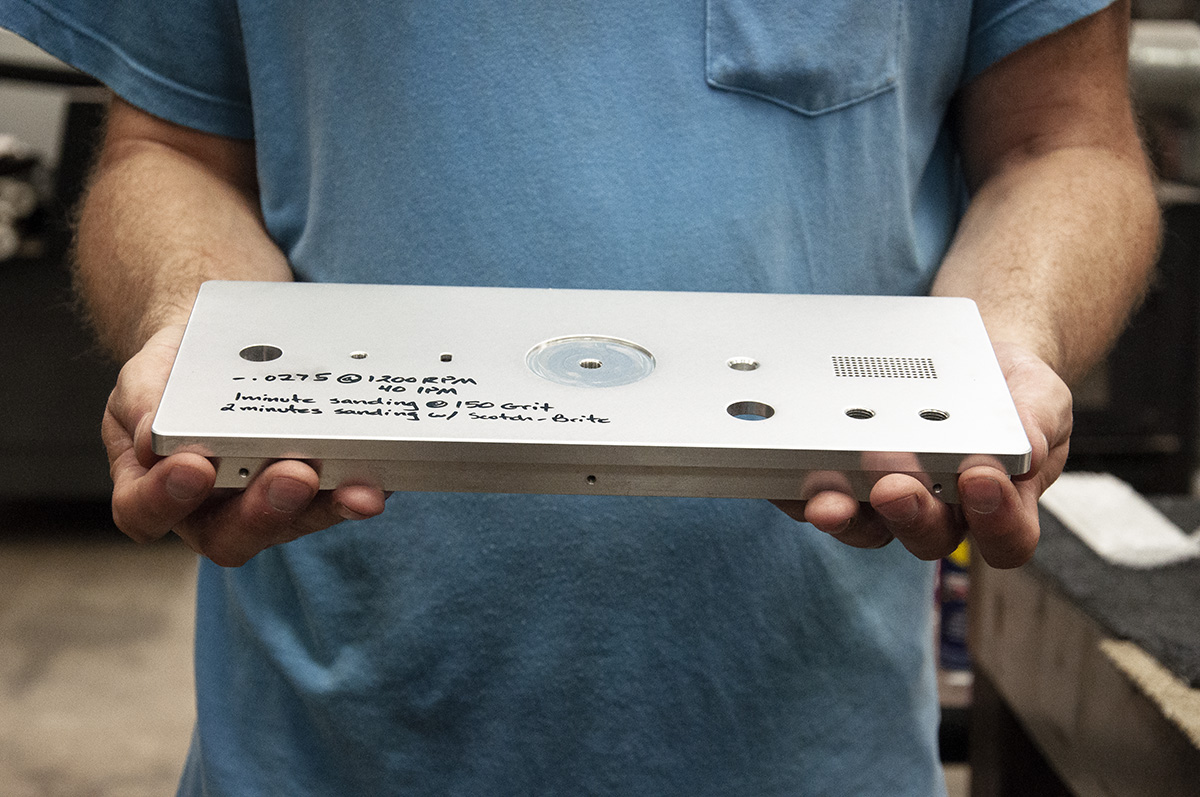

Richlite Speaker

CNC Routing MDF

CNC Routed Plywood

Laser Engraved Richlite

CNC Routing Plywood

CNC Routing Richlite

Request an Estimate

Composite Materials

At Tektonics, we excel in machining a wide range of composite materials, tailored to suit the unique requirements of our clients. Our expertise encompasses:

Plywoods: We specialize in machining plywoods known for their strength and versatility, including:

Birch Plywood (Baltic Birch Plywood): Recognized for its durability, smooth surface, and strength, making it ideal for various structural and decorative applications.

Luan Plywood (Lauan Plywood): Valued for its lightweight nature and excellent machinability, it suits projects requiring precision and aesthetic appeal.

MDF (Medium Density Fiberboard): Known for its uniform density and smooth surface, MDF is ideal for applications where precision and consistency are paramount.

Richlite: A sustainable composite material made from recycled paper and resin. Richlite offers durability, strength, and a unique aesthetic for architectural and industrial applications.

Machining Capabilities

Tektonics leverages advanced CNC machining capabilities to deliver precision and efficiency in composite component manufacturing:

CNC Milling: Our CNC milling processes enable us to create intricate designs and precise shapes in composite materials, ensuring superior accuracy and repeatability.

CNC Routing: Leveraging state-of-the-art CNC routing technology, we efficiently cut, trim, and shape composite materials such as Birch Plywood, MDF, and Richlite to exact specifications, ensuring optimal fit and performance in diverse applications.

Whether you require prototyping, small-batch production, or high-volume manufacturing, Tektonics combines technical expertise with industry-leading equipment to fulfill your composite machining needs. Discover how Tektonics can elevate your projects with superior quality and reliability in every composite component we machine.

Areas of Expertise

-

Industrial Design

Our design team translates user needs to turnkey solutions and works to develop products primed for production.

-

Prototyping

Prototyping new designs is second nature to us. We are highly skilled at rapidly testing and proving concepts for any manufacturing project.

-

Machining

Our team ensures your part is designed with manufacturing in mind and is highly skilled at producing low and high volume production runs.

-

Materials & Finishes

Our shop machines a wide variety of metal, plastic, and wood including stainless steel, aluminum, brass, polycarbonate, and plywood.