.

DeVore Fidelity

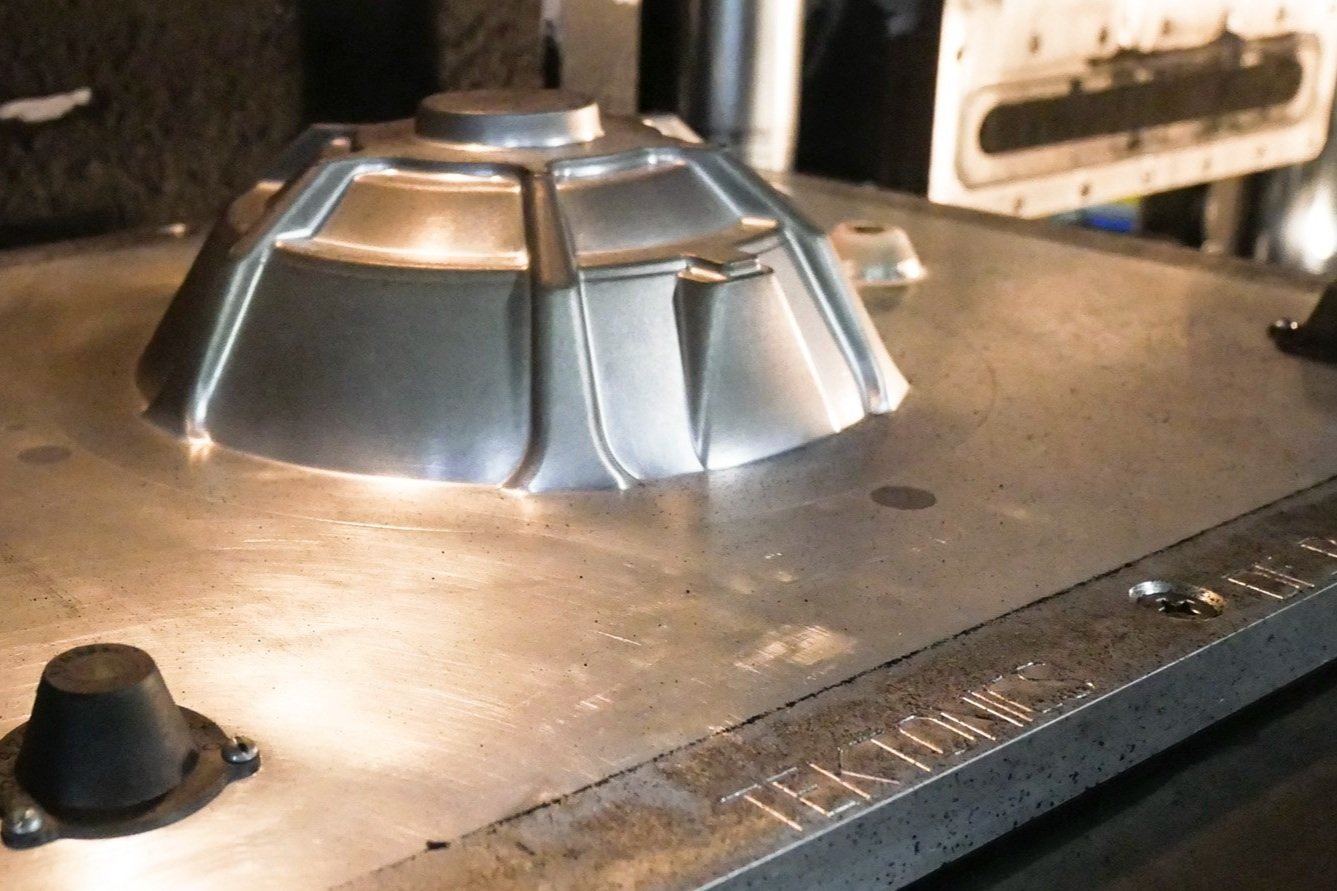

Bronze Speaker Driver Baskets

Bronze Machining, Casting, Machine Fixture

Our long history in architectural metalwork, ornamental finishes, and CNC machining processes were a crucial basis for DeVore’s trust that we would deliver.

Our Client, DeVore Fidelity, came to us with a unique challenge, to work with them and their driver manufacturer, Seas Fabrikker, to develop a proprietary, high-efficiency driver with a sand cast bronze basket. This was outside of the business model for Seas.

The unusual shape, tolerances, and cosmetic requirements required defined an enjoyable puzzle for our team to solve.

Castings for these driver baskets pose much greater challenges than those from a simpler, more uniform casting geometry. This project required small run with older manufacturing tech (sand casting) to supply these custom machined castings. Each machining project presents unique challenges in fixturing - holding the work piece properly while its cut. This is the art of a machinist. You have to hold onto strangely shaped parts rigidly and repeatably while cutting metal with metal which subjects the work to violent forces.

By the end of the project we had designed and manufactured the foundry tooling, a sample run, and a production run of 100 castings with several iterations and refinements to incorporate for future production runs for DeVore Fidelity.

Machining The Casting

The Casting Process