Design and Manufacturing of Metal Components

With a steadfast commitment to excellence and advanced CNC machining capabilities, we specialize in transforming a diverse array of metal materials into finely crafted components that meet the highest standards of quality and performance. Whether you're looking for superior strength and durability or custom hardware designs in metal machining, Tektonics is your trusted partner for turning concepts into reality.

CNC Milling Stainless Steel

CNC Machined Steel with Tapped Hole

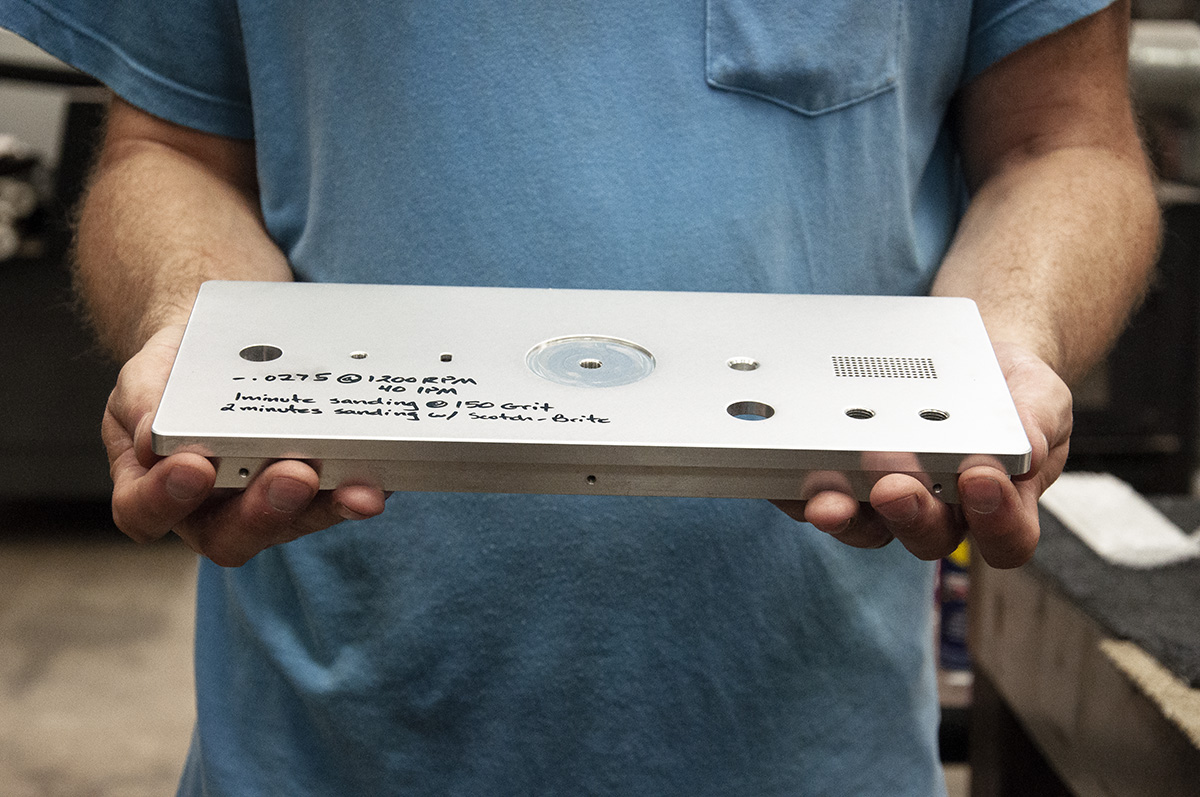

Finishing Aluminum

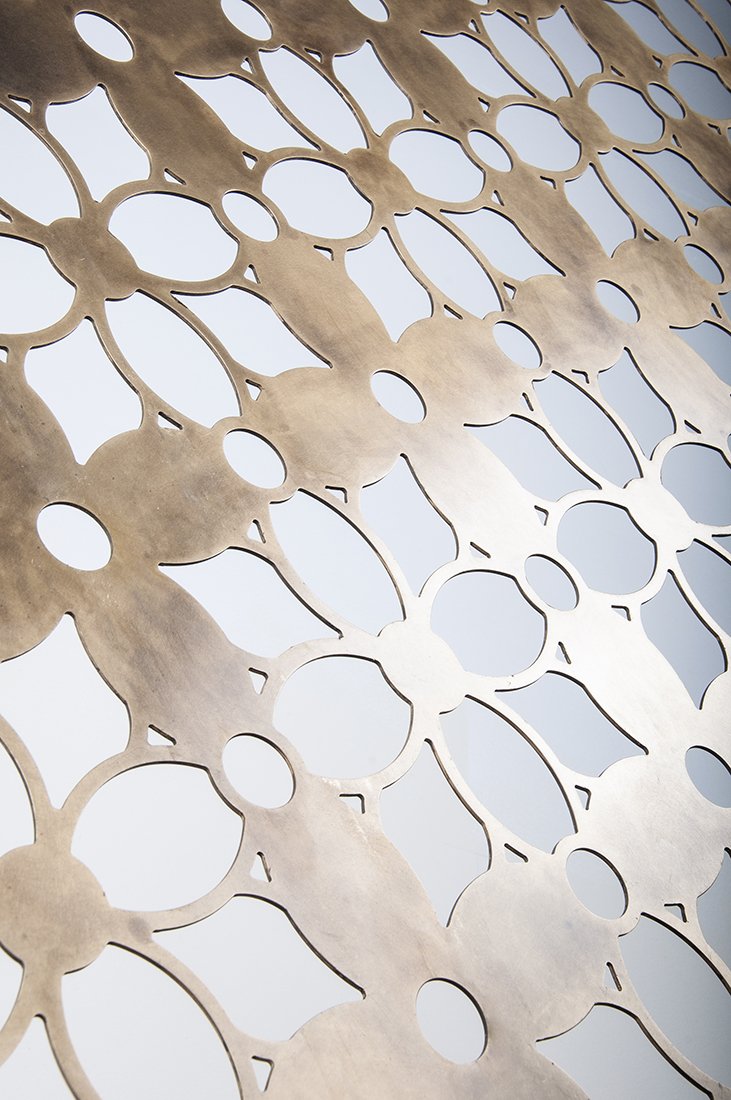

CNC Routed Brass

CNC Turned Aluminum

CNC Machining Aluminum Hardware

Laser Engraved Bronze

CNC Machined Aluminum

CNC Milling Metal

Stainless Steel French Hinge

CNC Machined Aluminum Hardware

CNC Machined Aluminum Hardware

CNC Machined Steel

CNC Turned Metal

CNC Machined Aluminum

CNC Machined Stainless Steel

CNC Machined Aluminum

CNC Turning Stainless Steel

Request an Estimate

Metal Materials

At Tektonics, we excel in machining a wide range of metals, tailored to suit the unique requirements of our clients. Our expertise encompasses:

Aluminum: Known for its lightweight, corrosion resistance, and versatility, aluminum is a popular choice for numerous applications across industries.

6061 Aluminum: Offering excellent mechanical properties and weldability, 6061 aluminum is ideal for structural applications requiring strength and durability.

6063 Aluminum: Recognized for its good surface finish and excellent corrosion resistance, 6063 aluminum is often used in architectural applications and automotive components.

Brass: Valued for its aesthetic appeal, corrosion resistance, and electrical conductivity, brass is commonly used in decorative and functional applications.

Bronze: Renowned for its strength, durability, and wear resistance, bronze is favored for bearings, gears, and intricate sculptures.

Copper: Known for its conductivity, ductility, and antimicrobial properties, copper is essential in electrical and plumbing applications.

Cold Rolled Steel and Hot Rolled Steel: Cold-rolled steel offers a superior surface finish and tight tolerances, while hot-rolled steel is ideal for structural and industrial applications requiring strength and toughness.

Stainless Steel: Distinguished by its corrosion resistance and strength, stainless steel is essential in environments demanding durability and hygiene.

303 Stainless Steel: Featuring excellent machinability and corrosion resistance, 303 stainless steel is suitable for precision machining applications.

304 Stainless Steel: Known for its versatility and ease of fabrication, 304 stainless steel is widely used in food processing, architectural, and industrial applications.

316 Stainless Steel: Offering superior corrosion resistance, especially in harsh environments, 316 stainless steel is ideal for marine and chemical processing applications.

Machining Capabilities

Tektonics leverages advanced CNC machining capabilities to deliver precision and efficiency in metal part manufacturing:

CNC Milling: Our CNC milling processes enable the creation of complex geometries and precise tolerances in metal components, ensuring exceptional accuracy and repeatability.

CNC Turning: With CNC turning capabilities, we manufacture cylindrical parts with exacting precision and surface finishes that meet stringent specifications.

CNC Routing: Utilizing state-of-the-art CNC routing technology, we efficiently cut, trim, and shape non ferrous metal materials to exact dimensions, ensuring optimal fit and performance.

Whether you require prototyping, small-batch production, or high-volume manufacturing, Tektonics combines technical expertise with industry-leading equipment to fulfill your metal machining needs. Discover how Tektonics can elevate your projects with superior quality and reliability in every metal component we machine.

Areas of Expertise

-

Industrial Design

Our design team translates user needs to turnkey solutions and works to develop products primed for production.

-

Prototyping

Prototyping new designs is second nature to us. We are highly skilled at rapidly testing and proving concepts for any manufacturing project.

-

Machining

Our team ensures your part is designed with manufacturing in mind and is highly skilled at producing low and high volume production runs.

-

Materials & Finishes

Our shop machines a wide variety of metal, plastic, and wood including stainless steel, aluminum, brass, polycarbonate, and plywood.