Virginia Department of Aviation

Trailer Coupling Device

Part Analysis and Redesign

The VDOAV came to us with a broken component (pictured on the left) necessary to transport their aircraft.

In the redesign (pictured on the right), we elected to use aluminum instead of plastic for durability and made changes to improve the ease of use and strength of the part.

The Broken Part

-

The original plastic trailer coupling snapped during use. Photo provided by VDOAV.

-

Our client requested the Ball Lock Clevis Pin be replaced with a more secure nut and bolt.

-

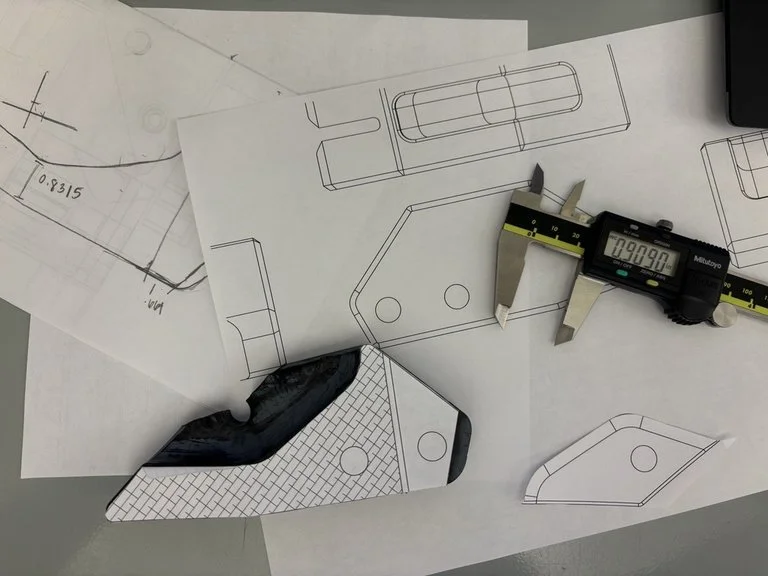

Capturing the inside curve to ensure the accuracy of the redesign.

Comparing the Parts

The new trailer coupling design adds extra material over the hole that failed on the original part and replaces the ball lock pin with a 3/8-16 bolt & a large enough counterbore for a socket.

The Redesign Features

-

The 3/8-16 bolt slots in perfectly and can then be secured on the other side with a socket

-

Machining the part out of aluminum and adding extra material around the hole that failed will increase the longevity and durability of the part